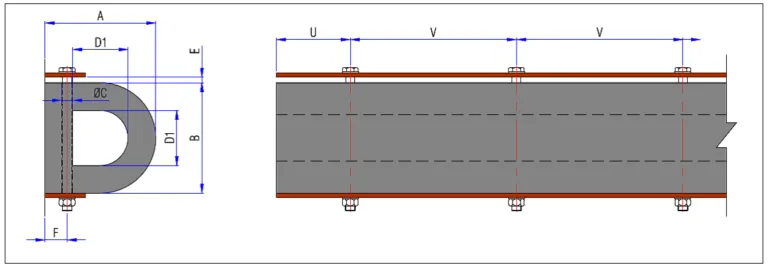

| Type | A | B | D1 | øC | E | F | U | V | Flat bar | Bolt size |

| LDD 100 | 100 | 100 | 50 | 15 | 10 | 25 | 90-130 | 200-300 | 50 x 6 | M12 |

| LDD 150 | 150 | 150 | 75 | 20 | 12 | 30 | 110-150 | 250-350 | 60 x 8 | M16 |

| LDD 200 | 200 | 200 | 100 | 25 | 15 | 45 | 130-180 | 300-400 | 80 x 10 | M20 |

| LDD 250 | 250 | 250 | 125 | 30 | 20 | 50 | 140-200 | 350-450 | 100 x 10 | M24 |

| LDD 300 | 300 | 300 | 150 | 30 | 25 | 60 | 140-200 | 350-450 | 110 x 12 | M24 |

| LDD 350 | 350 | 350 | 175 | 35 | 25 | 70 | 140-200 | 350-450 | 120 x 12 | M30 |

| LDD 400 | 400 | 400 | 200 | 35 | 30 | 80 | 140-200 | 350-450 | 130 x 15 | M30 |

| LDD 500 | 500 | 500 | 250 | 35 | 30 | 100 | 140-200 | 350-450 | 130 x 15 | M36 |

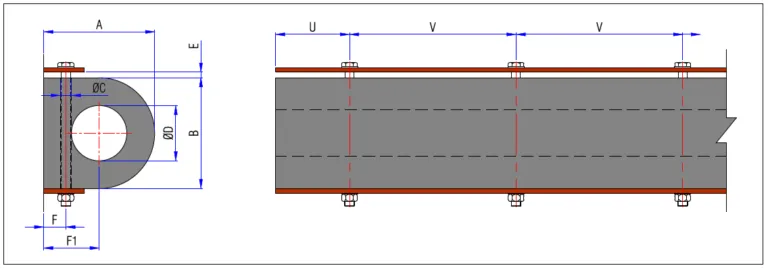

| Type | A | B | øC | øD | E | F | F1 | U | V | Flat bar | Bolt size |

| LDO 100 | 100 | 100 | 15 | 50 | 10 | 25 | 50 | 90-130 | 200-300 | 50 x 6 | M12 |

| LDO 150 | 150 | 150 | 20 | 75 | 12 | 30 | 75 | 110-150 | 250-350 | 60 x 8 | M16 |

| LDO 200 | 200 | 200 | 25 | 100 | 15 | 45 | 100 | 130-180 | 300-400 | 80 x 10 | M20 |

| LDO 250 | 250 | 250 | 30 | 125 | 20 | 50 | 125 | 140-200 | 350-450 | 100 x 10 | M24 |

| LDO 300 | 300 | 300 | 30 | 150 | 25 | 60 | 150 | 140-200 | 350-450 | 110 x 12 | M24 |

| LDO 350 | 350 | 350 | 35 | 175 | 25 | 70 | 175 | 140-200 | 350-450 | 120 x 12 | M30 |

| LDO 400 | 400 | 400 | 35 | 200 | 30 | 80 | 200 | 140-200 | 350-450 | 130 x 15 | M30 |

| LDO 500 | 500 | 500 | 35 | 250 | 30 | 100 | 250 | 140-200 | 350-450 | 130 x 15 | M36 |

D Fender – Standard Design for General Use

A D Fender is the most commonly used type, offering reliable protection for small—to medium-sized vessels, docks, and port structures. Its D-shaped design moderately absorbs impacts and remains flexible enough to fit flat and curved surfaces. D Fenders are widely used in piers, jetties, and boat hulls where a cost-effective yet durable solution is required. They come in different sizes and can be tailored to fit specific needs. They help absorb energy effectively and minimize surface damage.

DD Fender – Extra Thickness for Heavy-Duty Applications

A DD Fender is a reinforced version of the standard D Fender, featuring a double-chambered design. This design improves impact resistance, making it ideal for tough marine uses like tug boats, shipyards, and busy docking areas. These fenders are commonly found in high-traffic ports and shipyards where heavy loads and frequent docking require superior protection.

DO Fender – Hollow-Core Structure for Better Flexibility

A DO Fender has an oval-shaped hollow core, making it more flexible and lightweight than DD Fenders. This design balances impact absorption and adaptability, making it suitable for areas with space constraints or structures that require customized fender solutions. DO Fenders are often used in floating docks, pontoons, and offshore structures where a compact yet effective fender is needed. The DO Fender’s unique design enables it to fit tight spaces while maintaining durability and performance.

Weather & Wear Resistance

Made from high-grade rubber, D Fenders withstand harsh weather, saltwater exposure, and UV radiation. Their durability ensures long-term use without compromising performance, even in tough marine conditions.

Flexible & Versatile Installation

D Rubber Fenders offer many mounting options, allowing for installation on flat, curved, or angled surfaces. These fenders are ideal for use on tugboats, ports, and offshore platforms. Their adaptability ensures reliable protection across different marine settings.

Low Maintenance & Cost-Effective

Designed for minimal upkeep, these fenders provide long service life with reduced maintenance efforts. Their durability lowers replacement costs, offering a budget-friendly solution for marine protection.

Superior Shock Absorption

These fenders effectively disperse impact forces, minimizing damage during berthing and docking operations. Their high-energy absorption capability protects vessels and port structures, preventing costly repairs.

Tugs & Boats

Tugboats rely on D Fenders to absorb shock during towing and docking operations, ensuring safe maneuvering while preventing hull damage.

Vessels

From cargo ships to fishing boats, these fenders provide reliable protection against collisions during berthing, reducing the risk of structural wear and tear.

Barges & Pilot Boats

Designed for heavy-duty marine activities, D Rubber Fenders safeguard barges and pilot boats from impact forces when navigating tight docking spaces.

Ports & Docks

Used extensively in harbors and terminals, these fenders protect vessels and dock structures, preventing costly repairs and enhancing operational efficiency.

Offshore Platforms

D Rubber Fenders are vital in ensuring safe docking at offshore oil rigs and platforms, where strong currents and vessel movement pose docking challenges.

Industrial Applications

D Fenders are utilized not only in marine environments but also in loading areas, warehouses, and heavy machinery zones. They serve as a protective buffer against accidental impacts and help prevent equipment damage.

When it comes to marine impact protection, Lion Rubber stands out as a trusted manufacturer of high-quality D Fenders. Our commitment to innovation, durability, and customer satisfaction makes us the preferred choice across various industries.

Industry Experience & Expertise

With years of experience in marine rubber fenders, we understand the challenges in harsh marine environments. Our engineered solutions ensure maximum protection for vessels, docks, and offshore structures.

Custom Manufacturing & Design

Every marine project is unique, and we offer tailor-made D Fenders to match specific sizes, shapes, and performance requirements. Whether you need standard D Fenders, DD Fenders, or DO Fenders, we provide the perfect fit for your application.

Compliance with International Standards

Quality and safety are our top priorities. Our D Rubber Fenders are manufactured to meet global quality standards, ensuring reliability, longevity, and resistance against extreme marine conditions.

Proven Performance & Client Satisfaction

Trusted by leading ports, shipyards, and offshore industries, Lion Rubber’s D Fenders has delivered proven impact protection for countless marine projects. Our focus on precision engineering and customer support ensures long-term satisfaction.

Vessel Size, Docking Frequency & Impact Force

The size and weight of a vessel determine the impact energy during docking. Frequent docking or high-impact conditions require thicker, more durable fenders like DD Fenders for added protection.

Selecting the Right Type (D, DD, DO)

The type of D Fender plays a crucial role in its effectiveness. D Fenders are ideal for general-purpose marine applications, offering moderate impact absorption. DD Fenders provide thickness and are stronger, which makes them ideal for tough docking conditions. On the other hand, DO Fenders have a hollow core, which makes them more flexible and reduces stress on the mounting structures. Choosing the right type depends on the specific docking conditions and vessel requirements.

Material Quality & Durability

High-quality marine-grade rubber ensures resistance to wear, UV exposure, salt water, and extreme weather. Investing in premium D Rubber Fenders enhances longevity and performance, reducing maintenance costs.