Menu

Home » Products » Lion Dock & Harbour Accessories » Quick Release Hooks

Quick Release Hooks (QRH) enable mooring lines to be quickly and easily released, even under full load conditions. A variety of mounting options exist for the quick release hook. Typically a cast QRH base is used for new installations. To upgrade older facilities, fabricated hook bases can be designed to suit existing hold-down bolt patterns to replace bollards or old QRHs. THM hooks can also be retrofitted to existing bases from other suppliers, considerably reducing on-site civil works.

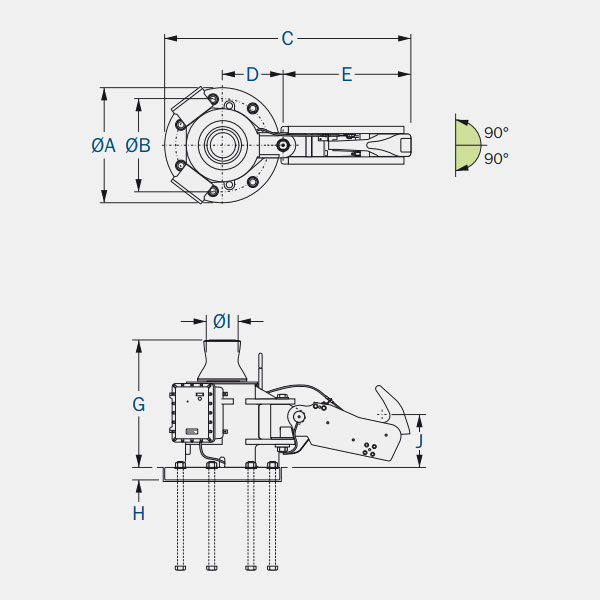

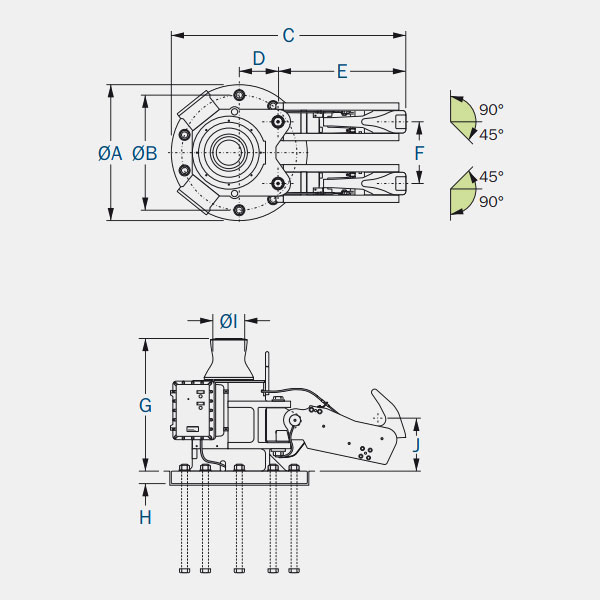

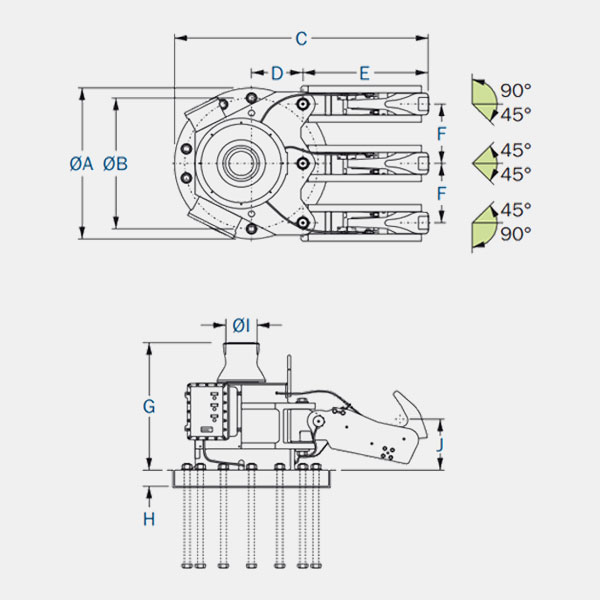

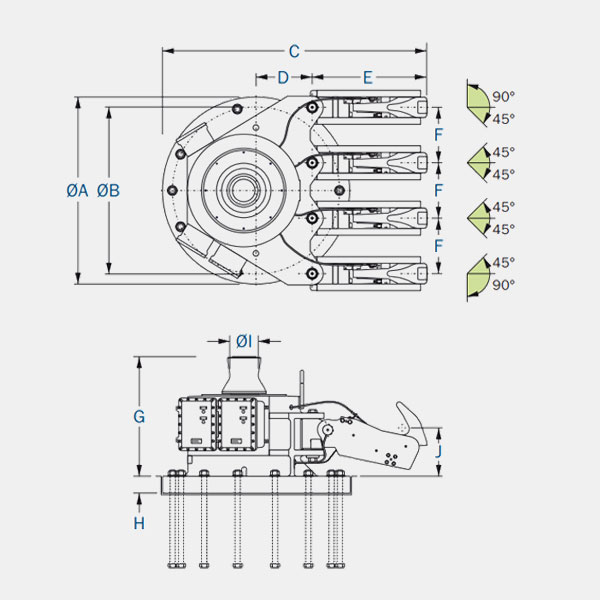

| Hooks | A | B | C | D | E | F | G | H | I | J | Anchors | Quantity |

| 45 Series | ||||||||||||

| Single | 1100 | 900 | 2060 | 550 | 960 | – | 1220 | 120 | 305 | 480 | M56 × 1000 | 4 |

| Double | 1100 | 900 | 1945 | 435 | 960 | 450 | 1220 | 120 | 305 | 480 | M56 × 1000 | 5 |

| Triple | 1300 | 1100 | 1980 | 370 | 960 | 510 | 1220 | 120 | 305 | 480 | M56 × 1000 | 6 |

| Quadruple | 1500 | 1300 | 2150 | 440 | 960 | 450 | 1220 | 160 | 305 | 480 | M56 × 1000 | 10 |

| 60 Series | ||||||||||||

| Single | 1100 | 900 | 2020 | 550 | 920 | – | 1220 | 120 | 305 | 430 | M56 × 1000 | 4 |

| Double | 1100 | 900 | 1905 | 435 | 920 | 450 | 1220 | 120 | 305 | 430 | M56 × 1000 | 5 |

| Triple | 1300 | 1100 | 1940 | 370 | 920 | 510 | 1220 | 120 | 305 | 430 | M56 × 1000 | 6 |

| Quadruple | 1500 | 1300 | 2110 | 440 | 920 | 450 | 1220 | 160 | 305 | 430 | M56 × 1000 | 10 |

| 75 Series | ||||||||||||

| Single | 1100 | 900 | 2020 | 550 | 920 | – | 1220 | 120 | 305 | 430 | M56 × 1000 | 4 |

| Double | 1100 | 900 | 1905 | 435 | 920 | 450 | 1220 | 120 | 305 | 430 | M56 × 1000 | 5 |

| Triple | 1300 | 1100 | 1940 | 370 | 920 | 510 | 1220 | 120 | 305 | 430 | M56 × 1000 | 6 |

| Quadruple | 1500 | 1300 | 2110 | 440 | 920 | 450 | 1220 | 160 | 305 | 430 | M56 × 1000 | 10 |

| 100 Series | ||||||||||||

| Single | 1100 | 900 | 2125 | 550 | 1025 | – | 1220 | 120 | 305 | 440 | M56 × 1000 | 4 |

| Double | 1100 | 900 | 2010 | 435 | 1025 | 450 | 1220 | 120 | 305 | 440 | M56 × 1000 | 7 |

| Triple | 1300 | 1100 | 2045 | 370 | 1025 | 510 | 1220 | 120 | 305 | 440 | M56 × 1000 | 10 |

| Quadruple | 1500 | 1300 | 2215 | 440 | 1025 | 450 | 1220 | 160 | 305 | 440 | M56 × 1000 | 14 |

| 125 Series | ||||||||||||

| Single | 1100 | 900 | 2125 | 550 | 1025 | – | 1220 | 120 | 305 | 440 | M56 × 1000 | 4 |

| Double | 1100 | 900 | 2010 | 435 | 1025 | 450 | 1220 | 120 | 305 | 440 | M56 × 1000 | 7 |

| Triple | 1300 | 1100 | 2045 | 370 | 1025 | 510 | 1220 | 120 | 305 | 440 | M56 × 1000 | 10 |

| Quadruple | 1500 | 1300 | 2215 | 440 | 1025 | 450 | 1220 | 160 | 305 | 440 | M56 × 1000 | 14 |

| 150R Series | ||||||||||||

| Single | 1100 | 900 | 2150 | 575 | 1025 | – | 1270 | 120 | 305 | 465 | M56 × 1000 | 7 |

| Double | 1300 | 1100 | 2045 | 370 | 1025 | 590 | 1270 | 120 | 305 | 480 | M56 × 1000 | 10 |

| Triple | 1500 | 1300 | 2275 | 500 | 1025 | 590 | 1270 | 160 | 305 | 480 | M56 × 1000 | 14 |

| Quadruple | 2000 | 1780 | 2625 | 600 | 1025 | 590 | 1270 | 180 | 305 | 490 | M56 × 1000 | 14 |