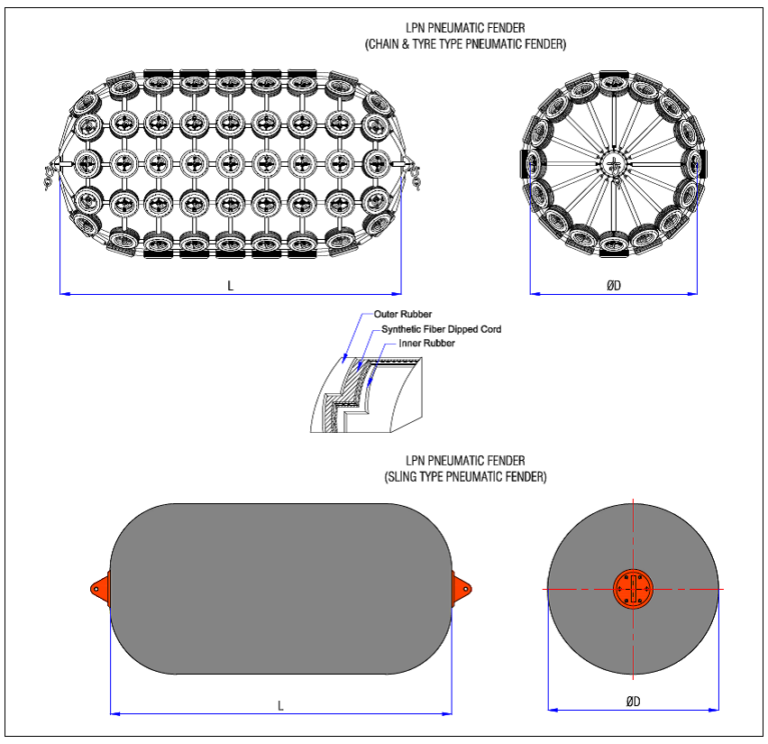

Lion Pneumatic Fenders are extensively used for operating as ship protection medium against collision among ship-to-ship transfers as well as ship-to-berthing. They are mainly used for large Vessels, Docks, Wharfs and Offshore platforms. Pneumatic fenders also come with chain-tyre net (CTN) fitted for added protection and without CTN.

| Type | O.D. | LENGTH | Safety Valve Setting Pressure (kg/cm²) | Testing Pressure (kg/cm²) | Weight on net tyre | ||

| Body weight Approx. (kg) | Approx. weight on net | ||||||

| Chain net (kg) | Wire net (kg) | ||||||

| LPN 500 | 500 | 1000 | - | 2 | 20 | - | - |

| LPN 600 | 600 | 1000 | - | 2 | 30 | - | - |

| LPN 660 | 660 | 1160 | - | 2 | - | - | - |

| LPN 700 | 700 | 1500 | - | 2 | 50 | 120 | 65 |

| LPN 1000 | 1000 | 1500 | - | 2 | 70 | 250 | 150 |

| LPN 1000 | 1000 | 2000 | - | 2 | 95 | 265 | 160 |

| LPN 1200 | 1200 | 2000 | - | 2 | 115 | 325 | 215 |

| LPN 1350 | 1350 | 2500 | - | 2 | 215 | 400 | 275 |

| LPN 1500 | 1500 | 3000 | - | 2 | 280 | 465 | 325 |

| LPN 1700 | 1700 | 3000 | 1.8 | 2 | 375 | 590 | 450 |

| LPN 2000 | 2000 | 3500 | 1.8 | 2 | 510 | 1125 | 570 |

| LPN 2500 | 2500 | 4000 | 1.8 | 2.5 | 775 | 1390 | 875 |

| LPN 2500 | 2500 | 5500 | 1.8 | 2.5 | 1025 | 1900 | 1350 |

| LPN 3300 | 3300 | 4500 | 1.8 | 2.5 | 1725 | 2200 | 1700 |

| LPN 3300 | 3300 | 6500 | 1.8 | 2.5 | 2230 | 3600 | 2650 |

| LPN 3300 | 3300 | 10600 | 1.8 | 2.5 | 2900 | 5950 | 4490 |

| LPN 4500 | 4500 | 9000 | 1.8 | 2.5 | 4650 | 5850 | 4350 |

| LPN 4500 | 4500 | 12000 | 1.8 | 2.5 | 6000 | 8200 | 6000 |

| SIZE | Internal Pressure (kg/cm²) | Design Deflection (%) | Energy Absorption (ton-mtr) | Reaction Force (ton) |

| LPN 500 X 1000 | 0.5 | 60 | 0.69 | 6.45 |

| LPN 600 X 1000 | 0.5 | 60 | 0.905 | 7.49 |

| LPN 660 X 1160 | 0.5 | 60 | 1.05 | 9.40 |

| LPN 700 X 1500 | 0.5 | 60 | 1.81 | 13.89 |

| LPN 1000 X 1500 | 0.5 | 60 | 3.21 | 18.41 |

| LPN 1000 X 2000 | 0.5 | 60 | 4.61 | 25.91 |

| LPN 1200 X 2000 | 0.5 | 60 | 6.41 | 29.91 |

| LPN 1350 X 2500 | 0.5 | 60 | 10.31 | 42.89 |

| LPN 1500 X 3000 | 0.5 | 60 | 15.31 | 57.89 |

| LPN 1700 X 3000 | 0.5 | 60 | 19.31 | 63.89 |

| LPN 2000 X 3500 | 0.5 | 60 | 30.91 | 87.71 |

| LPN 2500 X 4000 | 0.5 | 60 | 66.51 | 138.21 |

| LPN 2500 X 5500 | 0.5 | 60 | 94.51 | 202.05 |

| LPN 3300 X 4500 | 0.5 | 60 | 117.61 | 188.71 |

| LPN 3300 X 6500 | 0.5 | 60 | 181.51 | 302.05 |

| LPN 3300 X 10600 | 0.5 | 60 | 306.71 | 525.71 |

| LPN 4500 X 9000 | 0.5 | 60 | 475.21 | 574.71 |

| LPN 4500 X 12000 | 0.5 | 60 | 647.31 | 798.41 |

| SIZE | Internal Pressure (kg/cm²) | Design Deflection(%) | Energy Absorption(ton-mtr) | Reaction Force(ton) |

| LPN 500 X 1000 | 0.8 | 60 | 0.90 | 8.61 |

| LPN 600 X 1000 | 0.8 | 60 | 1.21 | 10.05 |

| LPN 660 X 1160 | 0.8 | 60 | 1.60 | 14.05 |

| LPN 700 X 1500 | 0.8 | 60 | 2.61 | 18.21 |

| LPN 1000 X 1500 | 0.8 | 60 | 4.67 | 23.91 |

| LPN 1000 X 2000 | 0.8 | 60 | 6.31 | 33.81 |

| LPN 1200 X 2000 | 0.8 | 60 | 9.05 | 39.11 |

| LPN 1350 X 2500 | 0.8 | 60 | 14.29 | 56.31 |

| LPN 1500 X 3000 | 0.8 | 60 | 21.51 | 76.31 |

| LPN 1700 X 3000 | 0.8 | 60 | 26.71 | 84.05 |

| LPN 2000 X 3500 | 0.8 | 60 | 43.05 | 115.05 |

| LPN 2500 X 4000 | 0.8 | 60 | 92.71 | 181.71 |

| LPN 2500 X 5500 | 0.8 | 60 | 131.79 | 265.51 |

| LPN 3300 X 4500 | 0.8 | 60 | 164.05 | 347.61 |

| LPN 3300 X 6500 | 0.8 | 60 | 253.21 | 396.11 |

| LPN 3300 X 10600 | 0.8 | 60 | 428.31 | 691.11 |

| LPN 4500 X 9000 | 0.8 | 60 | 663.51 | 755.11 |

| LPN 4500 X 12000 | 0.8 | 60 | 903.69 | 1049.05 |

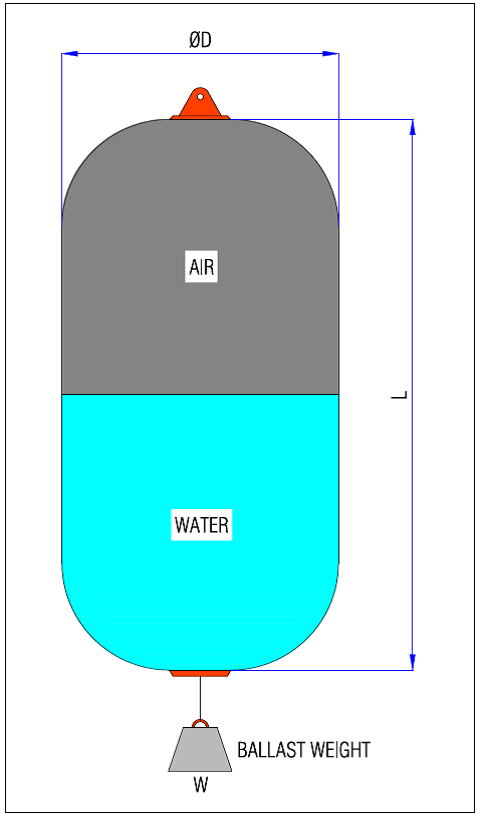

| Type | D | L | BALLAST WEIGHT (KG) | ENERGY ABSORPTION (KN-MTR) | REACTION FORCE (KN) |

| LHPN 10-30 | 1000 | 3000 | 500 | 15.05 | 90.04 |

| LHPN 12-30 | 1200 | 3000 | 500 | 41.05 | 152.04 |

| LHPN 15-45 | 1500 | 4500 | 1000 | 56.05 | 212.04 |

| LHPN 15-60 | 1500 | 6000 | 1000 | 58.05 | 310.04 |

| LHPN 17-72 | 1700 | 7200 | 1500 | 145.05 | 601.04 |

| LHPN 20-60 | 2000 | 6000 | 2000 | 161.05 | 587.04 |

| LHPN 25-65 | 2500 | 6500 | 2000 | 274.05 | 815.04 |

| LHPN 33-65 | 3300 | 6500 | 3000 | 621.05 | 1215.04 |

| LHPN 33-106 | 3300 | 10600 | 5000 | 610.05 | 1290.04 |

| LHPN 45-120 | 4500 | 12000 | 9000 | 1058.05 | 1980.04 |

Ensuring safe docking and berthing is crucial for offshore operations and large vessels. Pneumatic fenders act as a protective cushion, absorbing impact and preventing damage during mooring. Lion Rubber’s floating pneumatic rubber fenders are engineered for high performance, offering exceptional energy absorption and low reaction force to safeguard ships, docks, and offshore structures.

Designed for versatility, our pneumatic rubber fenders are suitable for various maritime applications, including ship-to-ship (STS) and ship-to-dock (STD) operations. With robust construction, superior durability, and adaptability to extreme weather conditions, these fenders provide long-lasting performance in the most demanding environments. Whether for offshore fender systems or large ship fenders, our solutions ensure maximum protection and reliability.

Pneumatic fenders are inflatable, air-filled fenders that protect ships, docks, and offshore structures during berthing and mooring. These fenders act as a cushion, absorbing impact energy and reducing the risk of damage to vessels. Their flexibility and shock-absorbing capability make them ideal for handling high-pressure impacts, especially in offshore and large ship fender applications.

Unlike conventional solid rubber or foam fenders, pneumatic rubber fenders have an inflated structure that provides superior energy absorption with minimal reaction force. This makes them particularly effective for floating pneumatic rubber fenders, as they adjust to water levels, ensuring continuous protection.

Widely used in fender offshore applications, these fenders are essential for ship-to-ship (STS) and ship-to-dock (STD) operations, ensuring a safe and efficient docking process. Their durability, low maintenance requirements, and ability to perform in harsh weather conditions make them a preferred choice in marine industries.

Lion Rubber’s pneumatic fenders are designed to provide long-lasting protection for ships, ports, and offshore structures. Built for durability and efficiency, they offer excellent shock absorption, reducing the risk of damage during berthing. Due to their advanced construction and reliable performance, these fenders are widely used in offshore fender applications, ports, and large ship docking.

Easy to Install and Remove

These lightweight pneumatic rubber fenders come with secure attachment points, making them easy to deploy and remove as needed. Their flexible design allows for quick adjustments, ensuring a hassle-free installation process.

Low Reaction and Hull Pressure

The air-filled structure of the floating pneumatic rubber fenders ensures minimal pressure on the ship’s hull, reducing the risk of structural damage while maintaining a strong cushioning effect. This makes them ideal for large ships, tankers, and offshore platforms.

As per ISO 17357 with 0.5 kg/cm² and 0.8 kg/cm² Internal Pressure

These large ship fenders are manufactured following international safety and quality standards. They provide consistent performance under different marine conditions. The pressure variations allow customization based on vessel size and impact force.

Robust Construction

These fenders are made with reinforced rubber layers and high-tensile synthetic cords, which are highly resistant to wear and tear. Their sturdy design enables them to withstand harsh weather, strong waves, and continuous impact without compromising efficiency.

Inflation Adjustability

These fender pneumatic solutions offer adjustable air pressure, allowing customization based on the size and weight of the vessel. This ensures maximum protection during berthing and docking operations.

Pneumatic fenders protect ships, offshore platforms, and marine structures. They are available in various types, each designed to meet particular requirements. The main types of pneumatic fenders are:

Standard Pneumatic Fenders

These fenders are air-filled and act as a cushion between ships and docks, absorbing shocks during docking, mooring, or collisions with other vessels. They are commonly used in ports, harbors, and other docking areas to prevent damage.

Hydro Pneumatic Fenders

These fenders use a combination of air and water to provide enhanced performance. Hydro pneumatic fenders are ideal for large ships and offshore operations, as they offer superior shock absorption and protection from high-impact forces. Their ability to handle heavier impacts makes them suitable for environments that experience extreme weather conditions and heavy-duty operations.

The hydro pneumatic fenders provide several advantages, including greater durability, better impact absorption, and the flexibility to withstand harsher marine conditions. They are particularly useful in offshore environments, ensuring maximum protection during critical docking or mooring operations.

Choosing the right fender is crucial when protecting your ship or offshore installation. Lion Rubber offers pneumatic fenders with unbeatable performance and reliability, trusted by maritime professionals worldwide for their superior design and quality.

Proven Performance

Pneumatic fenders by Lion Rubber are known for their excellent shock-absorbing capabilities and robust construction. With a reputation built on years of successful use in challenging offshore environments, our fenders provide the protection needed to prevent damage to your ship or platform.

Advanced Technology

We utilize the latest pneumatic fender technology, ensuring that each product meets the highest standards. Our fenders are designed to withstand high-pressure impacts, offering superior protection against harsh marine conditions. This ensures that your ship or offshore platform remains safe during docking, mooring, or rough weather.

Customization Options

We understand that each ship and offshore structure has unique needs. That’s why we offer customized solutions tailored for large ships, platforms, and maritime applications. Our fenders can be adjusted to meet your requirements from varying sizes to different inflation pressures.

Long-Term Cost Efficiency

Lion Rubber pneumatic fenders are built to last. Their high durability reduces the need for frequent replacements and costly repairs, offering long-term cost efficiency. With a low-maintenance design, they help improve ROI by saving you time and money on maintenance and replacements.

Proven Performance

Pneumatic fenders by Lion Rubber are known for their excellent shock-absorbing capabilities and robust construction. With a reputation built on years of successful use in challenging offshore environments, our fenders provide the protection needed to prevent damage to your ship or platform.

Advanced Technology

We utilize the latest pneumatic fender technology, ensuring that each product meets the highest standards. Our fenders are designed to withstand high-pressure impacts, offering superior protection against harsh marine conditions. This ensures that your ship or offshore platform remains safe during docking, mooring, or rough weather.

Customization Options

We understand that each ship and offshore structure has unique needs. That’s why we offer customized solutions tailored for large ships, platforms, and maritime applications. Our fenders can be adjusted to meet your requirements from varying sizes to different inflation pressures.

Long-Term Cost Efficiency

Lion Rubber pneumatic fenders are built to last. Their high durability reduces the need for frequent replacements and costly repairs, offering long-term cost efficiency. With a low-maintenance design, they help improve ROI by saving you time and money on maintenance and replacements.

Pneumatic fenders are essential in various maritime operations, offering unmatched protection for vessels and infrastructure. Below are some of the key areas where pneumatic rubber fenders are widely used:

Ports and Harbors

Pneumatic fenders provide crucial protection for port infrastructure, ensuring that ships and other vessels can dock without causing damage. The shock-absorbing properties of these fenders help prevent costly repairs to docks and vessel damage during the docking process.

Offshore Platforms

Offshore platforms, including oil rigs and drilling ships, are constantly exposed to challenging sea conditions. Pneumatic fenders protect these platforms from impacts during docking and mooring operations, ensuring safety and operational continuity in high-pressure offshore environments.

STS, STB Operations

Ship-to-ship (STS) and Ship-to-Barge (STB) operations require precise and secure positioning of vessels in close quarters. Fender Pneumatic are used during these operations to absorb shock and minimize the risk of damage during transporting goods or fuel between ships and barges.

Large Ships

For large ships like cargo carriers and tankers, safe mooring and docking are essential for maintaining safety and operational efficiency. Pneumatic fenders are specifically designed for large ship fenders, offering the durability and strength needed for heavy-duty use.

Floating pneumatic rubber fenders provide numerous advantages that make them a preferred choice for maritime protection. They offer unparalleled safety, adaptability, and cost efficiency in various docking and offshore operations.

Adaptability

Floating pneumatic rubber fenders are highly adaptable, suitable for varying water depths and changing marine environments. They maintain their effectiveness in shallow or deep waters, offering consistent protection for vessels across different docking scenarios.

Enhanced Ship Safety

One of the primary benefits of floating pneumatic fenders is their ability to reduce the risk of damage during docking and mooring. The shock-absorbing design of these fenders helps cushion impacts, protecting both the ship and port infrastructure from collisions. This ensures safer operations, even in challenging sea conditions.

Easy Deployment

The lightweight design of floating pneumatic rubber fenders makes them incredibly easy to deploy. Their quick setup saves valuable time during docking operations, especially in busy ports or offshore platforms where speed and efficiency are critical.

Reduced Maintenance Costs

Constructed from durable materials, floating pneumatic rubber fenders have a long lifespan and require minimal maintenance. Their robust design minimizes the need for frequent repairs, reducing long-term operational costs and contributing to overall cost efficiency.