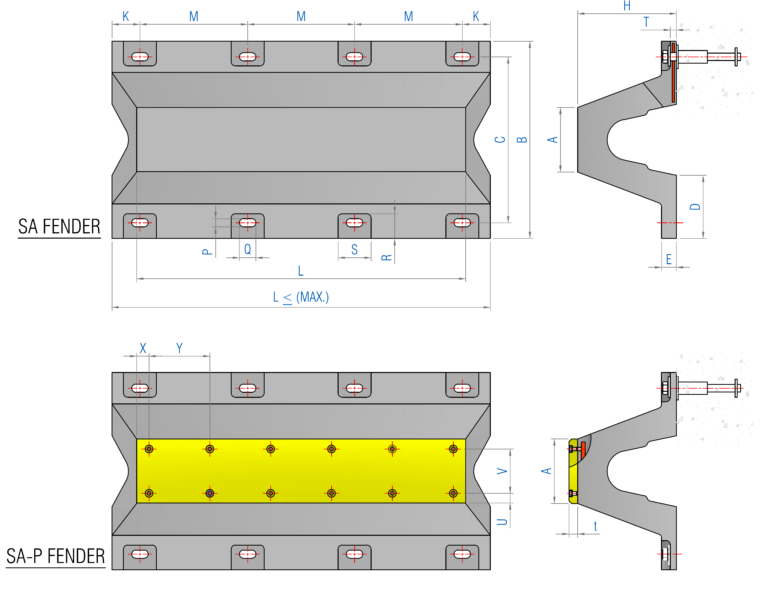

Lion Arch Fender is a most popular marine Jetty fender system used in all type of births & Jetty structures. It is available in all standard sizes and can be installed both vertically and horizontally. V Shape fender body can be bolted with UHMW-PE face pads or even steel panels.

| A | B | C | D | E | T | P x Q | R x S | Anchor | L | L (max) | M x N | K | |

|

LSA / LSAP 150H |

98 | 300 | 240 | 96 | 22.5 | 16.5 | 25 X 50 | 55 x 95 | M20 | 1000 | 1075 | 855 x 1 | 110 |

| 1500 | 1575 | 675 x 2 | 112.5 | ||||||||||

| 2000 | 2075 | 620 x 3 | 107.5 | ||||||||||

| 2500 | 2575 | 785 x 3 | 110 | ||||||||||

| 3000 | 3075 | 715 x 4 | 107.5 | ||||||||||

| 3500 | 3575 | 671 x 5 | 110 | ||||||||||

|

LSA / LSAP 200H |

131 | 400 | 320 | 128 | 30.0 | 19 | 29 x 58 | 75 x 105 | M24 | 1000 | 1100 | 860 x 1 | 120 |

| 1500 | 1600 | 680x 2 | 120 | ||||||||||

| 2000 | 2100 | 620 x 3 | 120 | ||||||||||

| 2500 | 2600 | 785 x 3 | 122.5 | ||||||||||

| 3000 | 3100 | 715 x 4 | 120 | ||||||||||

| 3500 | 3600 | 672 x 5 | 120 | ||||||||||

|

LSA / LSAP 250H |

164 | 500 | 410 | 160 | 37.5 | 20.5 | 32 x 64 | 90 x 125 | M27 | 1000 | 1125 | 865 x 1 | 130 |

| 1500 | 1625 | 680 x 2 | 132.5 | ||||||||||

| 2000 | 2125 | 620 x 3 | 132.5 | ||||||||||

| 2500 | 2625 | 790 x 3 | 127.5 | ||||||||||

| 3000 | 3125 | 715 x 4 | 132.5 | ||||||||||

| 3500 | 3625 | 673 x 5 | 130 | ||||||||||

|

LSA / LSAP 300H |

197 | 600 | 490 | 192 | 45 | 23 | 35 x 70 | 105 x 140 | M30 | 1000 | 1150 | 870 x 1 | 140 |

| 1500 | 1650 | 685 x 2 | 140 | ||||||||||

| 2000 | 2150 | 625 x 3 | 137.5 | ||||||||||

| 2500 | 2650 | 790 x 3 | 140 | ||||||||||

| 3000 | 3150 | 715 x 4 | 145 | ||||||||||

| 3500 | 3650 | 674 x 5 | 140 | ||||||||||

|

LSA / LSAP 400H |

262 | 800 | 670 | 256 | 60 | 31 | 41 x 82 | 120 x 165 | M36 | 1000 | 1200 | 900 x 1 | 150 |

| 1500 | 1700 | 700 x 2 | 150 | ||||||||||

| 2000 | 2200 | 635 x 3 | 147.5 | ||||||||||

| 2500 | 2700 | 800 x 3 | 150 | ||||||||||

| 3000 | 3200 | 725 x 4 | 150 | ||||||||||

|

LSA / LSAP 500H |

328 | 1000 | 840 | 320 | 75 | 34 | 47 x 94 | 140 x 180 | M42 | 1000 | 1250 | 930 x 1 | 160 |

| 1500 | 1750 | 715 x 2 | 160 | ||||||||||

| 2000 | 2250 | 645 x 3 | 157.5 | ||||||||||

| 2500 | 2750 | 810 x 3 | 160 | ||||||||||

| 3000 | 3250 | 730 x 4 | 165 | ||||||||||

|

LSA / LSAP 600H |

393 | 1200 | 1010 | 384 | 90 | 37 | 50 x 100 | 160 x 195 | M48 | 1000 | 1300 | 960 x 1 | 170 |

| 1500 | 1800 | 730 x 2 | 170 | ||||||||||

| 2000 | 2300 | 655 x 3 | 167.5 | ||||||||||

| 2500 | 2800 | 820 x 3 | 170 | ||||||||||

| 3000 | 3300 | 740 x 4 | 170 | ||||||||||

|

LSA / LSAP 1000H |

655 | 2000 | 1680 | 626 | 150 | 49 | 68 x 136 | 300 x 290 | M64 | 1000 | 1500 | 1100 x 1 | 200 |

| 1500 | 2000 | 800 x 2 | 200 | ||||||||||

| 2000 | 2500 | 700 x 3 | 200 | ||||||||||

| 2500 | 3000 | 865 x 3 | 202.5 | ||||||||||

| 3000 | 3500 | 775 x 4 | 200 |

| A | U | V | UHMW-PE face pads | |||

| X | Y | T | Bolt size | |||

| SAP 150 | 49 | 0 | 60–70 | 330–410 | 30 | M16 |

| SAP 200 | 65.5 | 0 | 60–70 | 330–410 | 30 | M16 |

| SAP 250 | 45 | 74 | 70–85 | 330–410 | 30 | M16 |

| SAP 300 | 50 | 97 | 70–85 | 330–410 | 40 | M16 |

| SAP 400 | 60 | 142 | 70–85 | 330–410 | 40 | M16 |

| SAP 500 | 65 | 198 | 70–85 | 330–410 | 50 | M20 |

| SAP 600 | 65 | 263 | 70–85 | 330–410 | 50 | M20 |

| SAP 1000 | 85 | 485 | 70–85 | 330–410 | 60 | M24 |

Lion Rubber’s LSA/LSAP arch rubber fenders are engineered to deliver exceptional energy absorption for heavy-duty berthing scenarios. Their simple yet strong arch design efficiently handles high-impact loads, protecting vessels and dock structures alike. These fenders are ideal for vessels—from tugboats to large cargo ships—and adaptable to various port and terminal environments.

Lion Rubber’s arch fenders are built with durable marine-grade materials and withstand harsh sea conditions while offering easy installation and low maintenance. With decades of expertise and a global presence, Lion Rubber provides custom-engineered fender solutions tailored to meet specific operational needs. These arch rubber fenders provide dependable and durable protection for commercial ports and offshore facilities.

Arch fenders are classic marine fender systems widely used in ports and harbors worldwide. Their distinctive curved design lets them absorb high amounts of impact energy while exerting low reaction forces on vessels and dock structures. This makes arch rubber fenders especially effective in protecting ships and piers during berthing, even under heavy-duty and frequent use conditions.

The curved shape of an arch fender allows it to compress and flex efficiently, distributing the impact force evenly to reduce damage. Lion Rubber’s LSA and LSAP series of arch fenders provide reliable protection with slight variations in design and load capacity, catering to different vessel sizes and marine environments. Both series are engineered to perform in harsh conditions while offering easy installation and maintenance.

Because of their durability and energy absorption capabilities, arch fenders are ideal for various applications, making them a trusted choice in marine protection worldwide.

Lion Rubber’s LSA/LSAP arch fenders combine robust design and practical functionality to deliver dependable marine protection. These fenders are engineered to meet the demands of medium-sized vessels, offering durability and ease of use in challenging berthing environments. Key features include:

Highly Durable:

Constructed from premium marine-grade rubber and reinforced materials, these arch fenders withstand harsh weather and repeated impacts, ensuring long service life.

Reliable for Medium Size Vessels:

Specifically designed to absorb energy from medium-sized ships, the LSA/LSAP fenders provide optimal protection without excessive reaction forces on the vessel or structure.

Good Shear Resistance:

The curved arch shape and quality rubber compounds resist shear forces caused by vessel movements, preventing damage to both the fender and the dock.

Easy to Install and Low Maintenance:

The simple, modular design allows quick installation with minimal downtime, while the materials used require little maintenance, reducing overall lifecycle costs.

Lion Rubber’s arch rubber fenders are engineered with precision to deliver high performance across diverse berthing conditions. Designed to balance energy absorption and low reaction forces, these fenders can be adapted to different installation styles and vessel types. Below are key technical aspects:

Dimensions and Material Grades:

Available in a wide range of sizes and cross-sections, Lion Rubber offers LSA and LSAP fenders in both standard and high-performance rubber compounds (Natural Rubber, EPDM, etc.) to suit site-specific requirements.

Energy Absorption and Reaction Force Chart:

Each fender is tested to deliver optimal energy absorption while maintaining low reaction forces. Detailed performance charts are available for review.

Installation Options

Depending on operational needs and dock design, fenders can be installed directly or with a steel frontal panel.

Mounting Compatibility:

Suitable for both wall-mounted systems and framed structures, offering flexibility in port infrastructure planning.

Lion Rubber’s arch fenders are trusted worldwide for their strength, durability, and versatility in various berthing scenarios. Built for tough marine conditions, they provide trusted protection where it’s needed most.

All Types of Jetty and Berth Structures:

From commercial terminals to fishing jetties, arch fenders provide reliable protection for docking areas exposed to varying vessel sizes and impact forces.

Offshore Platforms:

Designed to handle constant wave action and vessel contact, these fenders protect critical offshore assets with minimal maintenance needs.

Tugboat Berths:

Tugboats frequently dock and undock, requiring strong, wear-resistant fendering. Lion Rubber’s arch rubber fenders are ideal for such high-traffic zones.

Barge Berths:

Large, heavy barges need dependable fendering to avoid damaging berth structures. The LSA/LSAP series ensures safety during barge operations.

When it comes to reliable and long-lasting marine protection, Lion Rubber arch fenders are a trusted choice. Built for performance and durability, they are designed to confidently serve various berthing environments.

Proven Performance in Ports Around the World

Lion Rubber’s arch fenders are in use across global ports, delivering consistent results under tough berthing conditions, from commercial terminals to offshore docks.

Tailored Designs to Meet Project Requirements

Every port is different, which is why we offer custom solutions. Whether you need specific dimensions, materials, or installation configurations, we tailor each arch rubber fender to fit your site perfectly.

ISO-Certified Manufacturing Standards

Our production processes follow strict ISO certifications, ensuring each arch fender meets high-quality safety, performance, and durability standards.

Decades of Marine Fender Expertise

With years of experience in marine rubber engineering, Lion Rubber offers deep industry knowledge and reliable solutions trusted by engineers and port authorities worldwide.

At Lion Rubber, we understand that every marine project is unique. That’s why we offer flexible supply and customization services to meet the exact needs of our global clientele.

Worldwide Delivery and Support

Whether you're based in Asia, Europe, the Middle East, or the Americas, Lion Rubber ensures prompt delivery of our arch fenders with end-to-end support and documentation.

Custom Lengths, Mounting Types, and Material Options

From specific lengths and mounting styles to tailored material grades (like natural rubber, EPDM, or Neoprene), we adapt your arch rubber fenders to match your project requirements precisely.

Technical Guidance for Installation and Layout Planning

Our engineering team provides expert advice on installation strategies, layout optimization, and structural compatibility, ensuring smooth deployment and reliable long-term performance.

Looking for marine fenders that combine durability, performance, and easy installation? Lion Rubber’s arch fenders are engineered to deliver exactly that—tailored to your port or vessel’s needs.

Let’s build a safer, stronger marine docking solution—together.