Lion Roller Fenders are used on berth corners and dock entrances. These Fenders are usually used in restricted channels which help guide vessels.

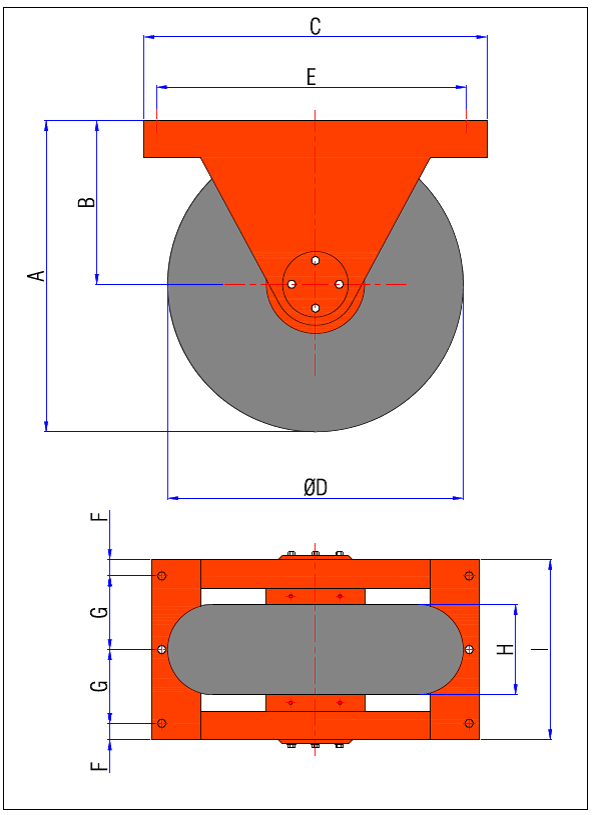

| Type | A | B | C | D | E | F | G | H | I | Anchor |

| LR 110-45 | 1150 | 610 | 1250 | 1080 | 1150 | 60 | 340 | 460 | 800 | 6 × M30 |

| LR 130-50 | 1400 | 740 | 1530 | 1320 | 1400 | 75 | 400 | 510 | 950 | 6 × M30 |

| LR 140-60 | 1450 | 765 | 1600 | 1370 | 1450 | 75 | 425 | 610 | 1000 | 6 × M30 |

| LR 175-70 | 1850 | 975 | 2050 | 1750 | 1850 | 125 | 500 | 690 | 1250 | 6 × M36 |

| LR 200-75 | 2100 | 1110 | 2300 | 1980 | 2100 | 150 | 550 | 765 | 1400 | 6 × M42 |

| LR 250-100 | 2700 | 1425 | 3000 | 2550 | 2700 | 200 | 700 | 895 | 1800 | 6 × M48 |

Roller fenders are essential for protecting vessels and dock structures during berthing operations. These fenders are made to absorb strong impacts and help guide ships safely in tight spaces like docks, locks, and busy ports. This rotation helps reduce shear forces on both vessels and berthing structures, minimizing damage and wear.

Lion Rubber offers heavy-duty roller fenders built to last in tough marine environments. Our fenders are engineered with high-quality materials to provide long-lasting durability and consistent performance even in high-traffic zones.

With years of experience and a trusted global presence, Lion Rubber provides roller fenders that meet international quality standards. Our roller fenders provide reliable protection for commercial ports, industrial docks, and offshore facilities, ensuring safe and efficient vessel operations.

A roller fender is a marine protection device designed to absorb impact and reduce damage during vessel berthing. Its unique design features a large rubber roller that rotates when a ship presses against it. This rotation helps minimize impact and shear forces on the vessel and the dock.

Typically, a roller fender consists of a strong steel frame, a durable rubber roller, and high-quality bearings that allow the roller to spin smoothly. This combination ensures the fender can handle heavy loads while protecting marine structures from wear and tear.

Roller fenders rotate with the vessel’s movement to effectively guide ships safely and reduce costly damage to docks and boats.

Our roller fenders are strong and efficient, providing excellent protection for vessels and docks. Here are their main features:

High energy absorption

Our roller fenders offer high energy absorption during berthing, helping to reduce damage to both ships and dock structures. This makes them ideal for protecting vessels in busy and demanding marine environments.

Robust design

Built with a strong steel frame and high-quality rubber rollers, these fenders withstand harsh marine conditions and heavy usage. Their tough construction ensures long-lasting durability even under continuous stress and pressure.

Low maintenance

Designed for easy inspection and upkeep, Lion Rubber’s roller fenders require minimal maintenance. This reduces downtime and maintenance costs, keeping marine operations smooth and efficient without compromising safety.

Low rolling resistance

The rollers are engineered to rotate smoothly with minimal friction. This reduces wear and tear on the fender and vessel, allowing ships to berth gently and safely even in tight or narrow docking spaces.

Lion Rubber’s roller fenders come with detailed technical specifications designed to meet diverse marine requirements. Below are the key technical aspects that highlight the quality and performance of our roller fenders:

Size Options & Roller Diameters

Available in various sizes to suit different vessel types and dock configurations. Roller diameters vary to accommodate diverse energy absorption needs and berth dimensions.

Materials Used

Constructed from premium natural rubber, this design provides excellent impact absorption. It features a robust steel frame and marine-grade components to ensure durability and resistance to harsh sea conditions.

Load Capacity & Deflection Limits

Designed to endure high loads with defined deflection tolerances, ensuring dependable protection against impacts while preserving structural integrity over extended use.

Performance Data & Resources

Detailed performance charts and technical data sheets, offering precise specifications to aid in system design and installation planning, are available for download.

Lion Rubber’s roller fenders provide dependable protection across many marine environments. Engineered to absorb impact and reduce damage, these fenders ensure the safety and longevity of vessels and structures.

Dry Dock Entrance:

Lion Rubber roller fenders guide vessels safely into dry docks by absorbing impact energy and minimizing friction. This prevents damage to dock infrastructure and ship hulls during docking operations.

Berth Corners:

Our fenders protect critical berth corners where vessels experience concentrated impact forces, helping to preserve the structural integrity of both the berth and the vessel during tight maneuvers.

Offshore Platforms:

Designed to cushion vessels as they moor alongside offshore platforms, Lion Rubber roller fenders reduce wear and tear, ensuring safer operations and extending platform lifespan.

Port Entrances and Ferry Terminals:

These roller fenders facilitate smooth and secure berthing in high-traffic areas like port entrances and ferry terminals, minimizing vessel downtime caused by collision damage.

Guide Systems for Bridge Structures:

Lion Rubber roller fenders act as protective buffers for bridge piers and support structures. They absorb collisions and protect these critical infrastructures from damage in harsh marine environments.

Choosing the right marine protection is crucial, and Lion Rubber stands out with unmatched expertise and innovation in roller fender solutions.

Innovative Engineering:

Lion Rubber integrates advanced design techniques to optimize roller rotation and energy absorption. This ensures superior fender performance even under the most demanding marine conditions.

Quality Assurance:

Every roller fender undergoes rigorous testing to meet international standards, guaranteeing consistent reliability and long service life.

Custom Fabrication:

Lion Rubber offers tailored solutions to fit unique berth configurations and vessel types, providing flexibility that meets specific operational needs.

Global Support Network:

With a worldwide presence, Lion Rubber ensures timely delivery, installation guidance, and after-sales service, helping customers maintain smooth marine operations.

Sustainability Focus:

Committed to environmental responsibility, Lion Rubber uses eco-friendly materials and processes, reducing the ecological impact of its products without compromising durability.

Lion Rubber ensures seamless worldwide shipping and reliable on-site support to meet the diverse needs of marine industries across the globe.

Worldwide Shipping:

No matter where your port or facility is located, Lion Rubber delivers roller fenders efficiently and securely, minimizing lead times.

Custom Roller Fender Systems:

We design and manufacture tailored roller fender configurations to perfectly fit unique port layouts and vessel types, maximizing protection and operational efficiency.

Expert Engineering Consultation:

Our experienced team provides professional guidance from initial design through installation, ensuring your roller fender system is optimized for performance and longevity.

Discover the power of Lion Rubber’s durable roller fenders tailored to your needs. Contact us today for expert guidance and custom solutions that ensure safe, efficient berthing every time.