Lion W Type fenders are installed on to the bow and the aft portions of Ocean going tugs, to product the hull of the vessel, against damages caused during pushing and pulling operations / towage. These fenders are installed in similar manner as those of key Hole Fenders.

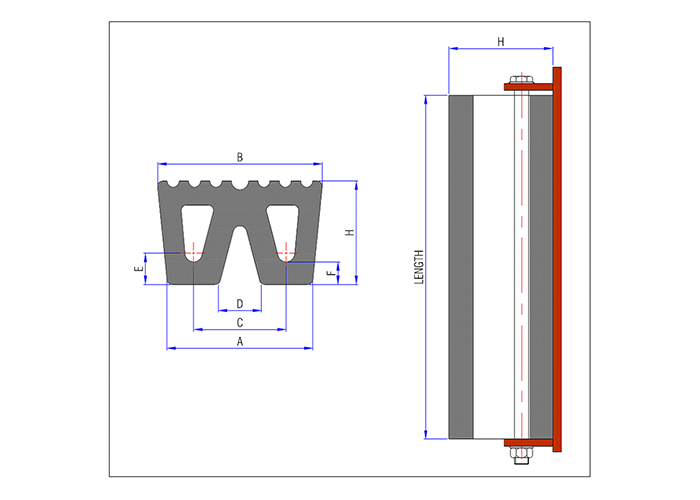

| Type | H | A | B | C | D | E | F | L(max) | FLAT BAR | PIN DIA. | R(min) |

| LW 200 | 200 | 280 | 320 | 180 | 100 | 67 | 50 | 2000 | 100 X 20 | 25 | 600 |

| LW 250 | 250 | 350 | 400 | 220 | 110 | 75 | 55 | 2000 | 120 X 20 | 30 | 800 |

| LW 300 | 300 | 426 | 480 | 269 | 135 | 90 | 65 | 2000 | 140 X 20 | 40 | 900 |

| LW 450 | 450 | 420 | 500 | 255 | 90 | 100 | 75 | 2000 | 150 X 20 | 40 | 1000 |

W fenders are a trusted and essential solution for tugboats and marine structures, offering unparalleled protection against impact. Their high energy absorption capabilities ensure vessels are safeguarded in even the most challenging conditions. Designed for maximum durability, these fenders play a crucial role in ensuring safe docking and berthing operations.

Built with rugged construction, W fenders are perfect for protecting marine infrastructure. Their unique design allows them to absorb heavy impacts while maintaining structural integrity, even in harsh environments. This makes them ideal for ports, docks, and other high-traffic areas.

At Lion Rubber, we prioritize quality and performance. Our W fenders are crafted to offer long-lasting protection with ease of installation. With flexibility and resilience, they meet the diverse needs of the marine industry, providing superior defense against damage during docking and tugging operations.

A W fender is a highly effective marine fender designed with a unique “W” shape, offering exceptional performance in high-impact marine environments. The distinctive shape of the fender provides excellent grip and contact with cylindrical or curved hulls, making it ideal for tugboats and other vessels that frequently operate in challenging docking and berthing conditions.

The W fender’s design allows for superior energy absorption, efficiently distributing the impact forces, which protects both the vessel and the docking structure from damage. This makes it particularly useful in tugboats, where the fender absorbs the force during towing or berthing operations.

Compared to D or cylindrical fenders, the W fender provides enhanced stability and better grip due to its unique shape, especially in high-impact situations. Its rugged design ensures long-lasting protection, even in demanding marine applications, making it the preferred choice for ports, docks, and tugboats that require durable and reliable fendering solutions.

Our W fenders combine advanced design and durability to ensure superior protection in challenging marine environments. Here are the key features that set them apart:

Extra Groove Structure

The extra groove structure in our W fenders provides enhanced grip, ensuring a secure fit and better energy absorption for high-impact marine operations, particularly on curved hulls.

Good Wear Resistance

Lion Rubber’s W fenders are designed for high wear resistance, ensuring they perform effectively in harsh marine environments, even under frequent impact and heavy usage.

Extreme Duty Design

Engineered for extreme duty, our W fenders withstand tough conditions, offering exceptional durability and superior protection for vessels, especially in high-energy docking and berthing situations.

Good Abrasion Resistance

With excellent abrasion resistance, W fenders maintain their protective quality even after prolonged contact with rough surfaces, providing long-term protection for vessels and docks.

Lion Rubber’s W fenders are versatile and designed to protect vessels and marine structures across various applications. Here’s how they’re used in the marine industry:

All Types of Tugs

Our W fenders are ideal for all types of tugs. They provide reliable protection during towing, docking, and ship-assist operations. Their robust design ensures the safety of the tug and the vessel being assisted.

Ocean-Going Tugs

Designed for heavy-duty operations, our W fenders are perfect for ocean-going tugs. They offer superior energy absorption and durability, essential for the challenging conditions found in open water.

Bridge Protection

W fenders are widely used to protect bridges from vessel impacts. Their strong design and high energy absorption capabilities reduce damage from accidental collisions with bridge piers or structures.

Pile Protection

W fenders protect piles in marine environments and prevent damage from ships and barges during docking or berthing. They safeguard piles against abrasive forces and reduce maintenance costs for marine structures.

Lion Rubber’s W fenders offer various options to meet specific needs across marine applications. They come in various sizes, lengths, and grades to suit different vessel types and operational requirements.

Customization Options

We understand that each project has unique requirements. Our W fenders can be customized with drilling, chamfering, and cutouts, allowing for tailored solutions to fit your specifications. Whether for mounting or specific design features, we provide flexibility to meet your needs.

Mounting Options

Our W fenders offer versatile mounting options for installation. They can be easily bolted on or secured with through-rod mounting, ensuring a secure fit for your vessel or marine structure.

Material Choices

Our W fenders are available in various material options, including natural rubber and synthetic compounds, to cater to different environmental conditions. This allows us to balance durability, flexibility, and cost-effectiveness depending on your operational environment.

Our W fenders provide reliable, durable protection for marine vessels, designed to withstand harsh conditions while offering easy installation and long-term performance.

In-house design and production:

We manage the entire production process, ensuring superior quality control and custom solutions to meet your requirements for W fenders.

Marine-tested materials:

Crafted from high-performance materials, our W fenders are rigorously tested to perform reliably even in challenging marine environments and offer superior durability.

Trusted globally:

Our W fenders are trusted by leading tugboat manufacturers and ports worldwide, known for their excellent impact protection and reliability.

Efficient support and shipping:

We offer quick production, timely shipping, and expert technical consultation, ensuring that your W fenders are installed efficiently and perform optimally.

Lion Rubber’s W fenders are designed for simple installation using standard marine fittings, either bolt-on or through-rod. Their versatile design ensures they can be mounted quickly and efficiently, providing maximum protection with minimal effort. This ease of installation makes them ideal for new setups and retrofitting existing marine structures.

In terms of maintenance, W fenders are built for longevity with minimal upkeep. They are highly resistant to UV rays, ozone, saltwater, and heavy impacts, ensuring they perform reliably in harsh marine environments. Regular inspections, especially after significant impacts, will help extend their lifespan. With their durable construction, these fenders require very little maintenance over time, offering a cost-effective solution for ongoing operations.